Benefits of Supplier Collaboration in Fusion Manage

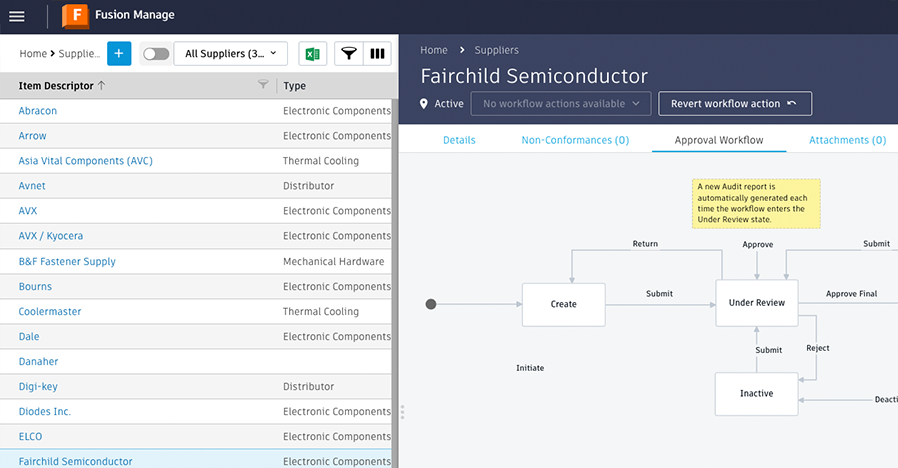

Autodesk Fusion Manage enables secure, streamlined collaboration with your suppliers by providing controlled external access to relevant data, documents, and workflows. Suppliers can view and interact with the most up-to-date versions of parts, BOMs, and specifications, reducing costly errors and miscommunication. All communication is centralised within the system, keeping feedback, approvals, and updates in one place. With built-in tracking and audit trails, you can monitor supplier activity and ensure compliance at every stage. By aligning external partners with your internal processes, Fusion Manage helps shorten lead times, improve visibility, and strengthen supply chain relationships.

🟧 Centralised Quality Processes

Manage all quality records—such as NCRs, CAPAs, and audits—in one unified, cloud-based system.

🟧 Integrated with Product Data

Link quality events directly to parts, documents, and change records for full traceability and context.

🟧 Configurable Workflows

Automate and standardise quality workflows, ensuring every issue follows a consistent, auditable path from identification to resolution.

🟧 Real-Time Tracking & Reporting

Monitor quality metrics and issue status in real time, with dashboards and reports tailored to your KPIs.

🟧 Improved Compliance

Maintain detailed records and approvals to meet ISO, FDA, or industry-specific standards with confidence.

🟧 Cross-Team Collaboration

Enable engineering, manufacturing, and quality teams to collaborate on quality issues within the same system—reducing silos and improving response times.

The only way for success

PLM is a balanced integration of People, Process, and Technology. If even one is missing or misaligned, the whole system suffers. Success requires all three working in harmony—33.3% effort isn’t enough; you need the full 100%. Click the words to see !